How Buttons Are Made - The Story of Buttons - Part 2

Pearl buttons and plastic buttons are perhaps the most interesting of all antique and collectible buttons, for completely different reasons.

- The pearl buttons were once so sought after that they were enormously expensive.

- The plastic buttons changed the way buttons were manufactured and have survived the test of time, being as much in use now, as they ever were.

Lustrous buttons From the Bed Of The Sea

Of the buttons made from non-plastic or other materials, pearl buttons have been the most expensive and some of the most treasured buttons of both today and yesteryear. After 1860, the pearl button began to come tot he fore, and by 1900 it was the most popular buttons of all.

The first pearl buttons were made of the pearl oyster's shell. These were known as ocean-pearl buttons because the pearl oyster is found in the ocean. Later, the shells of the fresh-water mussels were widely used, along with abalone shell.

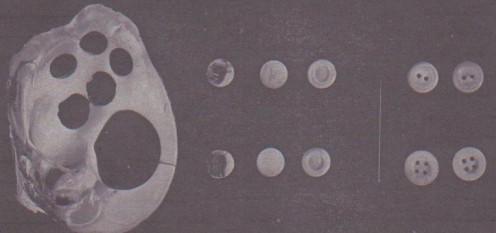

Shells for the ocean pearl buttons were secured chiefly from the water surrounding Australia and the East Indies. The shells were first soaked in water for several days in order to make them less brittle. They were next cut into blanks by tubular saws revolving at high speed.

The blanks were then split crosswise two or three times, depending on the thickness desired for the finished button. The back of each blank was either ground flat or else was rounded under an emery wheel. After grinding, the blanks were placed in chucks on an automatic pattern machine. As each blank was carried around the machine it met in succession tools that shaped it into any desired pattern, rounded its edges and drilled it with two or four holes. To give it back it's luster, the button was finally placed in a barrel of acid and then tumbled in a barrel of sawdust.

Fresh water pearl buttons were manufactured like ocean peal buttons, except that the blanks were not split crosswise.

The Process Of Making Pearl Buttons

Plastic Buttons

In the last two centuries, plastic buttons have come to be the most common type of button in use. The term plastic in the button industry means a synthetic material that can be molded into any desired shape. Plastics lend themselves excellently to mass production and there is a minimum of waste in the manufacture of buttons made from these materials.

Plastic buttons are made in different ways according to the material used. Let us take the case of galalith (casein), a milk product widely used in button making. The galalith is mixed with coloring amtter and other ingredients. The mixture is then fed into a machine that operates like a meat chopper. The mixture comes out of this machine in the form of plastic rods.

Sometimes sheets are made from these rods by pressing them in heated presses. Generally, however, the discs are sliced from the rods or punched from the sheets and then are hardened with formaldehyde. The discs are turned (this is, placed on a rotating lathe and brought in contact with a cutting tool). Then, they are carved, drilled, and polished.

Compression Molding Of Plastic Buttons

Some plastics, like Bakelite and Plaskon are made into buttons by the process known as compression molding. The plastic material is received by the manufacturer in the form of a dry powder.

First, by means of rotary pill machines, like those used in making medicinal pills, the powder is converted into preforms or pellets (pills) of about the size of the finished button. The preforms are molded in large cavity dies. In a die containing one hundred and forty cavities, one hundred and forty buttons are produced by each closing of the die!

After they have been molded, the buttons are tumbled about in a revolving barrel-like machine to remove excess material. Then, they are filed, drilled, and polished.

Injection Molding Buttons

Injection Molding of Buttons

A process called injection molding is also used to manufacture buttons from cellulose acetate plastics, such as Tenite. The plastic material is prepared in powder form. It is dumped into a hopper in the injection molding machine and goes into a heating chamber where it acquires the consistency of paste.

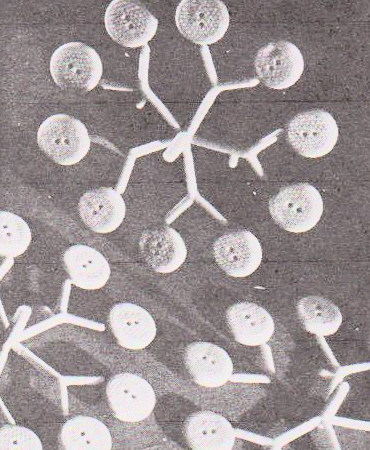

Then, a piston pushes it out of the heating chamber through a nozzle, and from the nozzle it is squirted into a mold. This mold has a number of cavities (sixteen or twenty-four, as a rule), each large enough to contain the material for one button. The cavities are connected with each other by means of little channels.

The plastic paste is squired into the mold while it is warm and "runny." It flowers along the little channels into the button cavities. The temperature of the mold is cold enough to cause the plastic material inside the cavities and in the channels as well, to harden almost instantly.

When the contents of the mold are ejected from the machine we have a number of buttons connected by little stems -- like buttons on a button tree.

The buttons are now broken from their stems by means of a buffing (cutting) machine, and the stems (or sprues, as they are called) are simply regoround into powder form and used as material for other buttons. From fifty thousand to two hundred and fifty thousand buttons can be made in a day from just a single machine by the injection molding method.

Celluloid Buttons

Celluloid buttons were manufactured in various ways. In the process known as frazing, blakcs (that is pieces of about the size of the finished button) are cut from large round rods. In some cases, the blanks were placed in holders called chucks, and then turned.

In other cases, the button was held stationary in the holding chuck, while a revolving blade made the design on the button.In making die-pressed celluloid buttons, round discs were cut from celluloid sheets and then pressed into shape by means of dies. Twisted celluloid buttons are made from thin rods softened in boiling water. The rods were then twisted by hand into all sorts of striking shapes.

If You'd Like To Know More!

- Button Collecting

If you love history, the buttons of the past 300 years mirror the great people and events of many eras. - Injection Molding

Injection Molding Professional - Nyloncraft, Inc. - Injection Molding Machine Starting-up Operation - Plastic Injection Molding Blog

Injection Molding Machine Starting-up Operation introduction: this post tell you the most detailed Injection Molding Machine Starting-up Operation. You can follow this instructions. - Welcome to iwantbuttons.com - a website for button collectors.